Case Studies

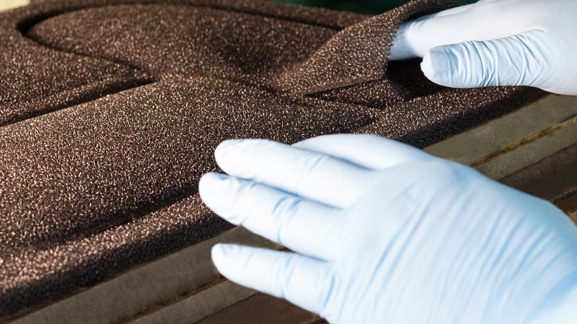

Infection Prevention

pinta medical collaborated with the customer from the onset of the project. We developed the chemistry to impregnate a moist paste into a foam material. The saturated foam is then adhered to a plastic substrate and sealed in an innovative airtight packaging for storage. Traditionally, foam is only impregnated with liquid. Therefore, the challenge was to identify a suitable foam material and the process needed to integrate the paste with the foam. pinta medical established a viable, efficient and repeatable process and modular system allowing for mass production and expansion.

Sensor

pinta medical was approached by a Pennsylvania startup to mold a mounting component for a sensing device that is affixed to the forehead of a patient during dialysis treatment. Assisting in material selection, pinta medical helped the customer find the right solution. To establish a viable process, a modular manufacturing process was set up. pinta medical facilitated bio burden testing and helped the customer bring the product to the market. Moving product through ISO 10993 standard testing, pinta medical was a valuable partner for our customer and has been involved since the inception of the product.

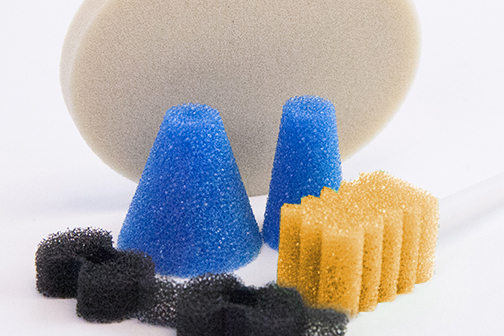

Fluid Waste Management Filter

pinta medical was contracted to develop and manufacture filters for a medical device company that builds complex fluid-management systems for hospital operating rooms. These systems are used in radiology, cystoscopy, endoscopy and urology to remove fluids from a patient and release the fluids into drainage. The filter provided by pinta medical cleans the fluids and removes non-fluid material, allowing for safe and easy disposal of waste materials—making operations more efficient and safer from infection, while eliminating the risk of handling fluids. Using pinta's foam know-how the medical division is offering viable and safe solutions for hospitals.